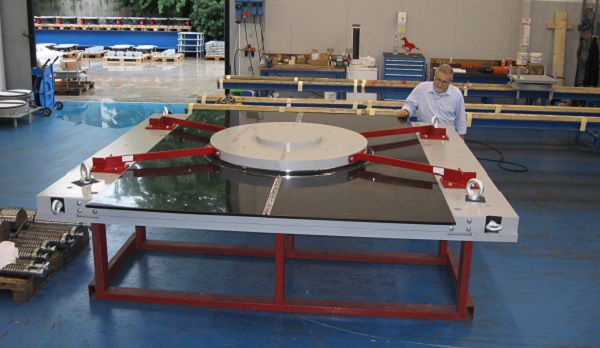

Spherical Bearings

Spherical bearings are the result of the most up to date technology. They have been developed for the bridges of the high speed railways but are suitable for all kinds of structures. Their main characteristics are the following:

- The sliding material is an innovative patented product, called HOTSLIDE, the result of research performed in collaboration with the Politecnico di Milano. The use of this product to substitute or PTFE allows the following great advantages:

- The service life of the bearings is extended by a factor at least 5. It is well known that for bridges subjected to heavy traffic the sliding material will continuously slide and will wear out after a certain period. HOTSLIDE has a resistance to wear at least 5 times greater than PTFE

- The range of temperature of the bearings is extended to -50°C instead of the -35°C for PTFE

- The dimensions of the bearings may be reduced because the characteristic compression strength of HOTSLIDE is more than twice that of PTFE.

- The design rotation of the spherical bearings is normally ± 3 (0,05 rad). This allows the compensation not only of the elastic rotations of the bridge but also that due to the inclination of the beams or the manufacturing and installation tolerances of the prefabricated beams. With such an allowable rotation the installation of prefabricated beams is greatly simplified, avoiding the use of expensive wedge plates. It is possible to achieve a considerable saving and to speed up the erection of the beams.

The fixed bearings may be equipped with a damping ring that will equalize the horizontal loads when it is necessary to install 2 or more fixed bearings on the same bearing axis. The damping ring avoids the uncertainty of the repartition of the horizontal load allowing it to be shared in equal parts between the different bearings.